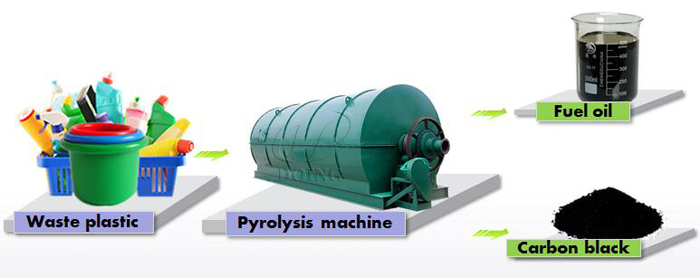

The 5th generation waste plastic to oil plant product introduction

Advantages of the 5th generation waste plastic to oil plant compare to the 4th generation

A:Add PLC system which can control the main parts of the whole system.

B:Add the other buffering tank for exhaust gas recycling ,and deliver gas to furnace for reburying.

C:Change from carbon black screw conveyor to carbon black bucket type lifting machine.

D:Add two automatic oil taking out pump .

E:Change from 5 vertical condensers to 2 horizontal condensers, one horizontal condenser equals to 5 vertical condensers.

F:Add one more insulation out side of the oil and water separator

The output:

1.45% crude oil

2.30% carbon black

3.10% steel wires

4.13% exhaust gas

5. 2% moisture

Product Details:

Place of Origin | Henan, China (Mainland) |

Brand Name | Doing |

Model Number | DY-2-10 |

Type | Tire Machine |

Tire Machine Type | Tire Recycling Machine |

Certification | CE |

18-hour Capacity | 10 tons |

Oil Yield | 4.5 tons |

Price: | FOB USD 50000~70000 / Set |

Minimum Order Quantity: | 1 Set/Sets |

Port: | Tianjin or Qingdao |

Packaging Details: | 1 flat rack and 40HQ |

Delivery Time: | 20 days |

Payment Terms: | T/T |

Supply Ability: | 30 Set/Sets per Month |

| Technical parameter of the 5th generation waste plastic to oil plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | waste plastic, waste tyre, waste rubber, | ||

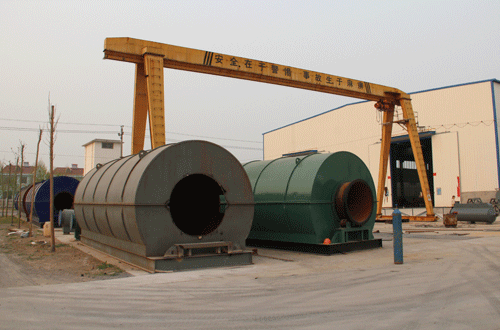

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Xinxiang Doing Renewable Energy Equipment Co., Ltd

Xinxiang Doing Renewable Energy Equipment Co., Ltd